ARRI: 100 Years Young

Munich Diary / Ron Prince

ARRI: 100 Years Young

Munich Diary / Ron Prince

BY: Ron Prince

In celebration of its one-hundredth birthday, ARRI invited British Cinematographer Magazine editor Ron Prince and co-publisher Alan Lowne, for a behind-the-scenes tour of its Munich headquarters during flaming June. Here’s a journal about what turned out to be a very special jaunt indeed.

Sunday, 7pm

So what does it take to become a centenarian? Often it’s attributed to a wee dram of whisky before bedtime. Sometimes it’s having walked the dog, or taken a bracing freshwater swim, twice daily in all weathers. Not sure this applies to a veritable camera and lighting business, whose business encompasses to the four corners of the earth, but at least we’re going to get some insight into ARRI’s longevity and its future plans during this trip. I wonder whether we’ll encounter any people in lab coats?

Alan and I are greeted at Munich’s Franz Josef Strauss airport by our personal driver, Andreas. The armrest cup-holder in the backseat of his fabulous Mercedes is stuffed with ARRI’s famous tradeshow Gummi Bears, especially for us. We’re whisked down the autobahn, checked into the hotel in The English Garden district, and find ourselves ordering Wiener Schnitzel for supper, before you can utter “Donner und Blitzen” – which the sultry weather is threatening outside.

Monday, 10am

“We work where other people like to come on holiday… welcome to ARRI,” is the greeting from Ursula, the chirpy receptionist at ARRI’s lighting manufacturing facility in Stephanskirchen, some 110km south of Munich. The journey here in Andreas’ wunder-car has certainly been wunder-bar – with the autobahn swooping through picturesque wooded vales and hills on this glorious summer morning. The neat-looking factory is tucked away in a dingly dell, beside an idyllic brook, across from paddocks that surround the family estate of ARRI co-founder’s son, Bobby Arnold. Must come on holiday here, it’s fabulous.

We meet Markus Zeiler and Markus Lampier, general managers of ARRI Lighting’s business unit, and Tino Schuldt, who oversees industrial engineering here. “It was a lumpy, bumpy ride to get to 100 years,” admits Markus Z. “During the 1990s the time and motion experts came in and recommended that ARRI close down its lighting division. But we like to look to the future, and someone within the senior management back then decided to keep it going.” Note to self: patience at the crease, plus fortuitous decisions make for a long innings.

As we amble through the large test studio, festooned with HMIs, fresnels and LEDs, we learn that ARRI’s lighting manufacturing business is going great guns. Here they turn out 50,000 Tungsten/Daylight lampheads plus LED fixtures per annum. Whilst there’s been a reduction in demand for Tungsten, LED is most definitely on the rise. For example, ARRI has sold over 28,000 SkyPanels worldwide to date, and they only launched in October 2015. Back in the UK, Pinewood MBS has accumulated the world’s largest stockpile of these. Overall, ARRI’s lighting business has seen a growth of 40% in the 2016-17 period over the previous year, making for a handsome turnover of over €100 million. The words “hot” and “cakes” spring to mind.

Although various parts, like spigots for example, are tailor-made by third-parties in Italy, Germany and Great Britain, and bulbs/LEDs come from trusted suppliers in Germany, Malaysia, Japan and Korea, the meticulous assembly is all done here. Some of the testing processes have been automated/robotised, but the products are lavished by the human touch to make sure they really shine.

“We rely on the experience of our workforce,” says Markus L. He reveals that it takes one person one day to make one ARRIMAX. One hundred SkyPanels are made per day (although they, indeed all lamps, are rigorously tested in lab-like conditions for two days before they’re ready for shipping, and any fixtures showing the merest trace of fragility or unreliability are promptly weeded out).

Do they mind copycat products creeping into the market from the Far East? “Not especially, because quality of light and reliability are the differentiators, and the thresholds are very high,” says Tino. “We have 15 years of experience in LED colour science, and know just how hard it is to create RGBW tuneable white light, and you can’t readily match the optics either. As ARRI also makes digital cameras, we do a lot of testing to optimise lighting quality for the digital sensor. Also, we are always reaching out to cinematographers, gaffers and our rental house partners for their feedback as to how we can make better products.”

Investment has been such that ARRI’s lighting division now has eight dedicated software engineers, focussed on writing some funky new, customisable lighting effects, available in the new Firmware 3.0 – such as candles/firelight, passing clouds, cops’ cars, fireworks, night clubs, lightning, paparazzi, strobes and pulses – along with no fewer than 46 pre-programmed matches to common light sources, including Tungsten, sodium vapour and fluorescents.

We pass an indoor football table, with green playing blue. Markus L reminds us that England wore an emerald strip during that painful penalty shoot-out at Euro ’96. Note: Thanks for that, but shows the winning spirit is vital when the chips are down.

Monday, 12:30pm

A wholesome canteen lunch, in lovely sunshine, beside that idyllic brook, which is teeming with trout. Just time for a quick photo of me and Al in front of a large print of the company founders, Richter and Arnold, with their film cameras on wooden sticks, and then we’re back in the marvellous Merc. Although Andreas is sticking to the Geschwindigkeitsbegrenzung, we’re back in time for our next appointment with two of today’s ARRI bosses – executive board members, Franz Kraus and Dr Jörg Pohlman.

"The original founders were filmmakers, an integral part of a close-knit filmmaking community that still exists today.

They made reliable products that worked, based on what people really needed, and gave ARRI its hallmark reputation for image quality, reliability and patient innovation."

- Franz Krauz, ARRI Executive board member

Monday, 3pm

ARRI’s HQ in Türkenstrasse, in the mellow University district, was originally a small shoemaker's shop, before ARRI’s founders, August Arnold and Robert Richter, took over the property. Incidentally, the “AR” of Arnold and “RI” of Richter make up the name ARRI. Today, across its various sites and divisions around Munich, and the wider Bavaria region, ARRI employs 500 people, and 1,500 people worldwide. ARRI remains a family-owned business, and occupies the same space, though the site has grown to the size of an entire city block.

Franz, who has helped steer the ship for 16 years, puts ARRI’s longevity down to healthy roots. “The original founders were filmmakers, an integral part of a close-knit filmmaking community that still exists today. They knew about all of the elements of filmmaking – camera, lights and post production – and developed a truly unique understanding of the processes, the industry, the people and the value chains. They made reliable products that worked, based on what people really needed, and gave ARRI its hallmark reputation for image quality, reliability and patient innovation. Of the original analogue camera companies that existed, only ARRI is still standing. So we are very proud to have reached this milestone, which was not necessarily a given, especially with the transition from analogue to digital.”

Indeed, that’s quite an achievement. Less than a decade ago, ARRI was predominantly an analogue business, and moving into the digital market was a crucial step to get right. But it wasn’t a sudden thing. We are reminded that ARRI’s success in laser film scanning and recording technology gave precious insight and knowledge into digital colour science, dynamic range and resolution, “so it was not such a great leap as you might imagine into digital imaging and digital cameras, although it did take a lot of funding,” says Franz.

He also fondly remembers the considerable contributions of Bill Lovell, former head of 3D and digital at ARRI Rental in the UK. “Bill was a very important figure, who was very close to reality and what was possible, who travelled the world for ARRI, and who was hugely responsible for what has become the ALEXA camera system today.”

Jörg says that with the advent of its digital wares, ARRI’s R&D team has tripled in size to over 100, and that the turnover on camera and lighting accessories has more than doubled during the last few years. They have now built and shipped over 70 ALEXA 65 cameras, an ARRI product available only through ARRI Rental.

“We find ourselves in a unique position with development capabilities, have a highly-competitive range of new products and accessories, and see lots more potential,” says Jörg. “We view any competition as a challenge, not a negative threat, and are very optimistic as we set our sights firmly on the future.”

Next year the company will expand into brand new premises. Carrying the project name ‘ARRIAL’, and centrally-located in Munich, it will provide 215,000sq/ft of space to accommodate 600 employees. That said, Jörg notes: “We’re mindful that rental companies spend money with ARRI, and we are keen to safeguard their investments with new upgrade paths for software and hardware, so that ARRI continues to make a good investment for them.”

Monday, 5pm

Next up is Stephan Schenk, MD of ARRI Cine Technik and general manager of the Camera Systems business unit. He gives us a quick tour of the impressive in-house museum, which features an Oscar statuette amongst many other gongs, plus an array of ARRI’s old and new cameras, all preserved behind glass. One is a charred and badly-bruised ALEXA, which still works. There’s Roger Deakins’ favourite old ARRIFLEX 535 film camera, before he switched to ALEXA, of course.

With all of this mighty history on display, Stephan talks about future developments in the areas of VR/AR/360. ARRI has recently cooperated with Radiant Images in LA, on a camera rig featuring ten ALEXA Minis. More about that tomorrow.

Trying to tease out any secrets regarding the next generation of cameras, he says, “It’s very easy to create a ‘wishlist’ of specifications for a camera – to shrink the form factor, make it lighter, improve the dynamic range, colour gamut, give it more pixels – but you have to balance all of those variables. What counts for us, and our customers, is to offer the best overall image quality, with the most pleasing skin tones and colours, with the best overall production value, that is quick and easy to operate, whilst providing data with reliability and efficiency for post houses. Ultimately it is about delivering a complete camera system – lenses, camera, accessories and workflow. That’s why the ALEXA SXT, for example, has 14 different shooting formats. So, yes, being a camera manufacturer we, of course, are working on new sensors and camera systems, but we will never put out an inferior product.” For anyone waiting for a 4K ALEXA, your patience is very much appreciated.

Last year ARRI snapped up the camera stabiliser system product group from Vitec. “Image stability is extremely important especially when you are working at higher resolutions. The TRINITY is a great addition to our product range and there is more to come,” Stephan says.

Monday, 6pm

Last night’s Wiener Schnitzel was so good, that it would seem churlish not to try it one more time. And guess what? It's equally as good at the local beer garden, where we’re having supper al fresco with ARRI’s head of corporate marketing and communications, Ute Böhringer-Mai, and two of her team, Reegan Köster and Heiko Meyer. We discuss – amongst the more trivial matters of fiendishly-long-German-compound-words – the digital revolution and need for ARRI to continually communicate its burgeoning offerings via print and social media. Celebrating its centenary, ARRI has conducted 300 interviews with industry professionals from all over the world – including Wim Wenders, Ang Lee and Roger Deakins to name a few. Previewed online, the teaser for The Filmmaker’s View grossed 33,000 views in one week.

The Filmmaker’s View will be launched on 12th September.

It’s been a long but fascinating day. Tired as newts, we settle down with more Donner und Blitzen outside to refresh the bedtime air.

Tuesday, 7.30am

We chomp on freshly fried eggs and bacon, amid a colourful delegation of families from India, who have come to meet their guru. Reflecting on what we’ve seen and heard so far, it strikes me that ARRI isn’t an old company. It’s effectively a brand new business, built on a 100-year pedigree. And they are making the most of their new digital faculties.

Tuesday, 9am

Back at HQ, we’re on a tour of the department where the ALEXA SXT, ALEXA Mini and AMIRA cameras are built. I lost count of how many camera bodies we saw at various stages of construction, but it can’t have been far off a hundred – with all of them already sold. Before shipping, every lump gets shaken and stirred for 30 minutes by a US military-grade machine, whose vibrations are so forceful the beast is kept in the basement to prevent damage to the building. This trauma is followed by a plunge into a freezer that reaches down to -40ºC, after which it gets baked in an oven that could cook your Sunday roast. These various ordeals take six hours.

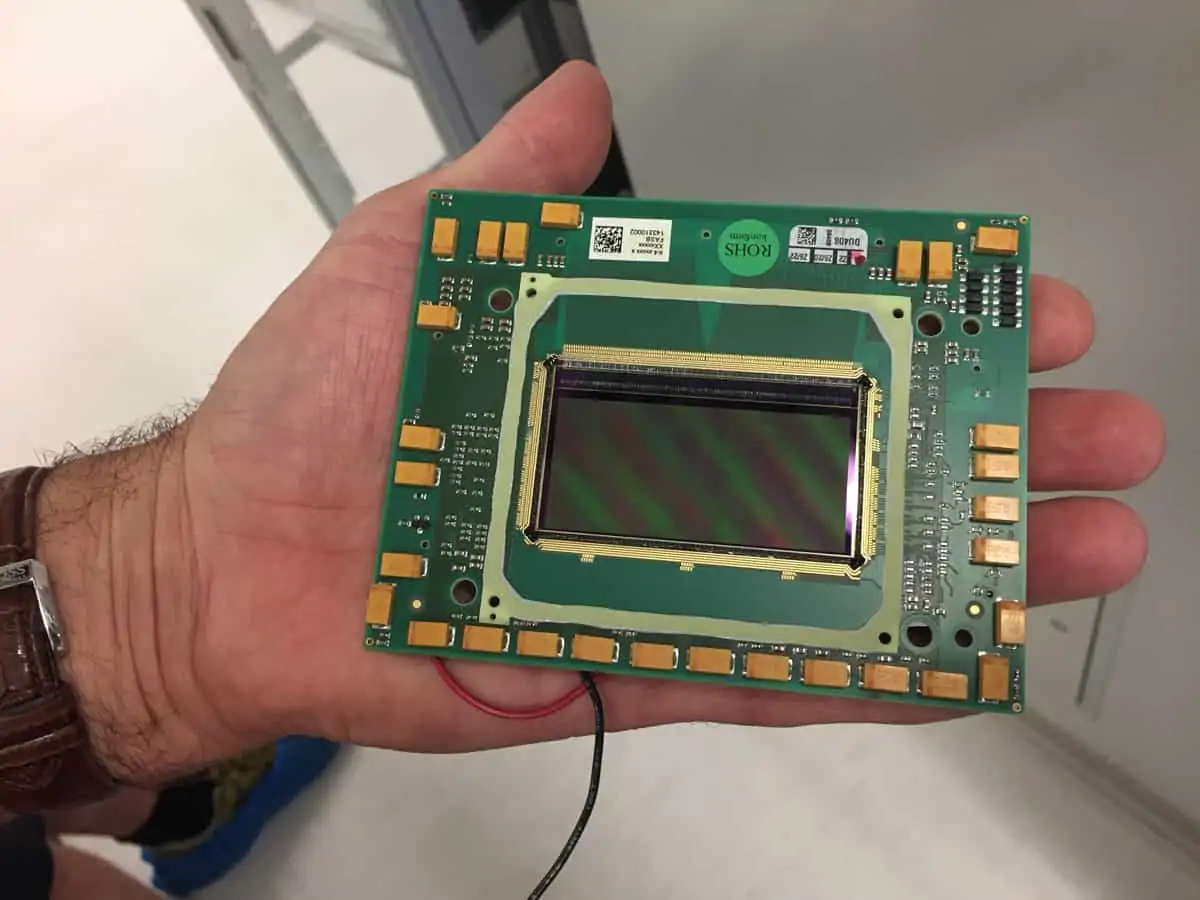

Next each sensor is calibrated, and tested for dead pixels with all manner of fixed pattern grads and filters. As if that wasn’t enough, there’s then a forensic scrutiny of all of the camera buttons and functions, like Bluetooth and Wi-Fi, plus dark room tests with Macbeth charts to see if the camera really is yielding 14-stops of dynamic range. The failure rate is low – less than one camera per day. After two days of scrutiny, the finished product is assembled, with the correct lens mounts and accessories, as per the customer order. “There’s no point in shipping a product that people cannot use immediately, and too many returns is not good for business or ARRI’s reputation,” says our guide, Daniel Schwerdtfeger.

Tuesday, 10:30am

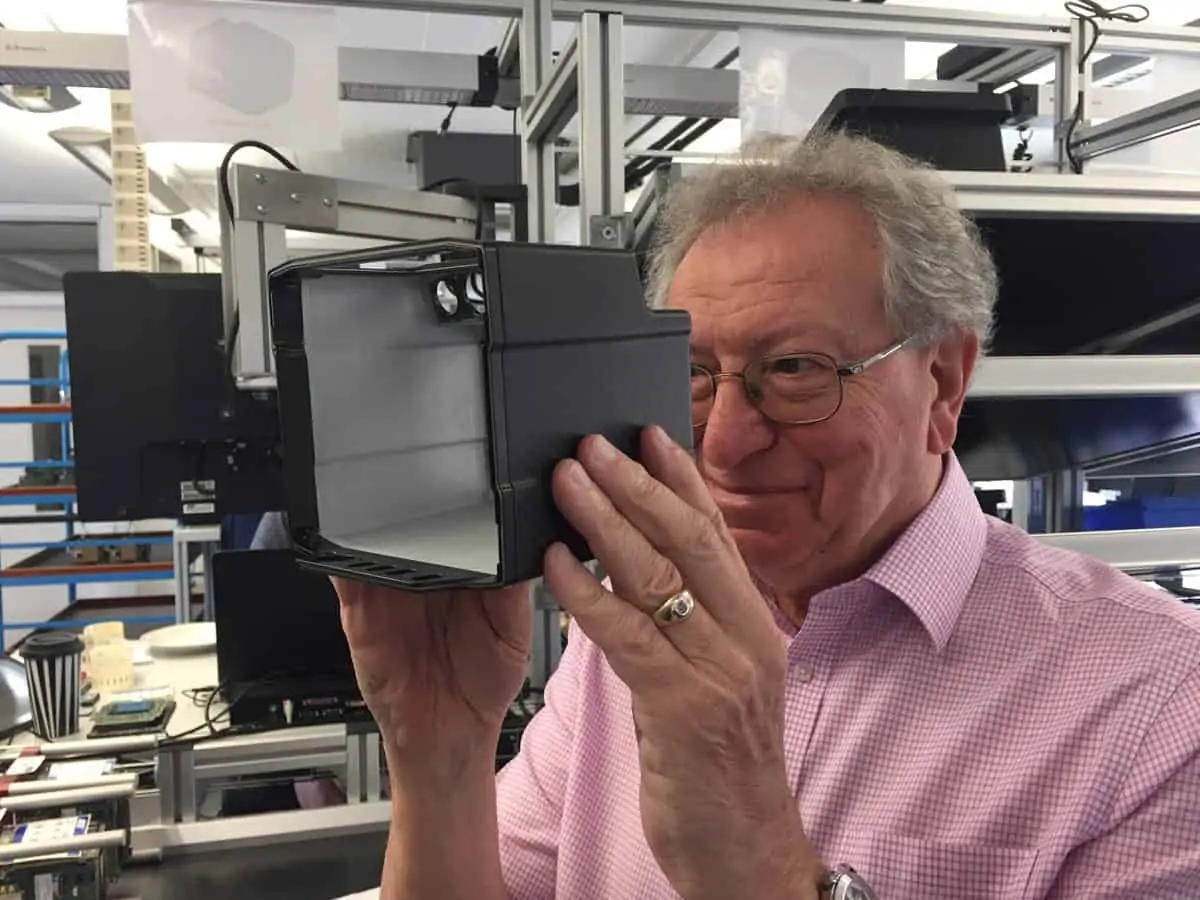

We are now entering a ‘clean zone’ where you have to wear a hat and blue overshoes. Where the technicians, in sealed-off glass rooms, are dressed as if they could be pioneering a cure for something nasty, or splitting the atom. This is where the ARRI-specified sensors for the ALEXA and AMIRA make holy communion with the boards that will fit into the camera body, before taking part in the Great Shake-off/Bake off we witnessed earlier. Siegfried Wetscheck, manager of bonding and cleanroom assembly, says the sensor bonding process involves pressure, vibration and 25 minutes of time to make the 960 teeny-tiny stitches that connect the sensor to the circuit board. Vorsprung durch Technik!

Tuesday, 12-noon

Also on the Türkenstrasse plot is ARRI Media, Creative Solutions and Post Production Services. Starting from the rooftop canteen garden, Michael Koch and Angela Reedwisch show us around numerous VFX, 3D animation, editorial, colour grading and motion graphics suites, where the creative producers and digital artists work on a variety of corporates and visualisations for BMW, Audi, Bosch and Volkswagen, as well as TV shows, commercials and features. One such up-and-coming project is the football feature Trautmann – produced by Robert Marciniak, Steve Milne and Chris Curling, with Daniel Gottschalk the DP – for which the team is recreating Wembley Stadium and Manchester City’s Maine Road of the 1950s, with plenty of crowd replication required.

We’re then given a trouser-shaking Dolby Atmos presentation by sound producer Michael Huber, in a brand new mixing studio. ARRI has another Atmos mixing stage at its separate branch over at Bavaria Film Studios. Beside ARRI’s facilities, the only place outside of the US for Dolby Vision post is London. We learn that ARRI’s Post wing now has a 50% market share in DCPs for the German market.

If we weren’t giddy enough by now, with all that swirling sound, there’s a special demonstration of ARRI’s pioneering work in interactive VR/AR/360, from Clarens Grollmann, which is hugely impressive. One sad note is they closed the ARRI film lab 18 months ago, greeted by tears of auf Wiedersehen.

Before we leave for lunch and then the airport, we’re handed the brand new ARRI Look Library, a book of LUTs akin to a Pantone swatch. The ARRI Post team came up with the idea of making and selling off-the-shelf LUTs, available to you for very little money. I can see this being a valuable resource and an excellent money-spinner.

Tuesday, 3pm

We’re leaving for the airport, brandishing family-pack bags of Gummi Bears and stylish ARRI jackets that will come in handy at Camerimage. Andreas’ tarmac-munching Merc makes short shrift of the schlep to Franz Josef Strauss.

So much more than a camera and lighting business, the digital world has opened up a myriad of new opportunities, and ARRI knows it’s in a marathon, not a sprint. Note: spread your wings, broaden your opportunities.

Serendipitously, a jogger runs by, wearing a T-shirt bearing a sentiment in yellow day-glow type that reads… “I’m good today, but will be much better tomorrow.” Seems to sum it up in a nutshell really. Happy 100th birthday ARRI, and thanks for a splendid trip.

CONGRATULATIONS ARRI!

Roger Deakins CBE BSC ASC

It seems I have been using ARRI cameras, lenses and lighting equipment for much of the company’s 100-year history. Well, I have for 35 of them. From film to digital, from the ARRI BL to the ALEXA Mini, it is my opinion that ARRI, both its company and equipment, continues to be second to none. Here’s to the next 100!

Oliver Stapleton BSC

ARRI’s 100th birthday – that’s special! I have been purchasing and renting ARRI cameras and lighting for almost 40 years. It is quite amazing to think this wonderful company is still with us, and is still run with the same spirit that it was founded. What is that spirit? Brilliant engineering based on user consultation. Thank you ARRI. May you continue this ethos forever!

Ben Davis BSC

I've been working with ARRI cameras my entire career – from a 16SR on my first student film to the 6K ALEXA 65 now, via many other ground-breaking varieties – the BL2, 2C, 535, 3C, 435… the list goes on. All were great and remain so. Always manufactured with the user in mind. Always reliable in tough conditions. Now it’s ARRI lighting fixtures that are breaking new ground, and it's a privilege to have them as another tool in a DP’s arsenal.

Anthony Dod Mantle DFF BSC ASC

The first time I visited ARRI in München was in the wake of a student film festival, where we were honoured with the first international graduation film prize. We visited the factory and its different departments, much the worse for severe visits to the bar.

Last year, approximately 30-years later, I was back working within the same walls, prepping Snowden for Oliver Stone. ARRI were immensely helpful through all departments – from their most experienced technicians and management, to the shop-floor testing facilities, even their in-house runners and trainees. Everyone was exceptionally service-minded and professional.

I have always enjoyed collaborating with ARRI, whether it’s in the UK, South Africa, or Germany. They listen. They remember. They advise elegantly. I will always look forward to returning to ARRI, and ARRI München, in particular, is the Holy Grail centre of their massive empire. My thanks and best wishes to you all.

Mike Valentine BSC

For over 30 years, I have had the pleasure of revealing the hidden beauty of the underwater world – in over 90 features, many TV dramas and commercials. Throughout this time, I’ve had the pleasure of either owning or using the wide variety of ARRI cameras.

Working underwater pushes you and your equipment to the limit. I have never had a major breakdown and always appreciated your advice and technical support, whether shooting at Pinewood or the middle of the Pacific Ocean. Thank you and congratulations!

Chris Menges BSC ASC

In 1957, aged sixteen, I was apprenticed to the outstanding American cinematographer/director Allan Forbes Jnr. His camera of choice was a little gem – the ARRI 11A. Allan was a superb teacher and 12 years later I shot my first feature, Kes, for Ken Loach. The little gem was by then the ARRI 11C. In its lead blimp, it was huge, taking two strong people to lift, but it made location sound possible. Now, years later, we can dance with a new little gem – the ALEXA Mini - and catch more than words! Thanks ARRI for making so much possible.

Michael Seresin BSC ASC

Congratulations on reaching a century. What an achievement – and still a family company. Your cameras and culture have been a part of my filmmaking life forever. Through rigour, innovation and imagination you have helped us all fly. Just wonderful.

Gavin Finney BSC

Congratulations on 100 years! ARRI’s cameras and lights have been an integral part of my imagemaking since I first pulled an ARRI 16mm BL out of its box and loaded a precious short-end at film school, and they’ve been with me ever since. Their cameras and lights work so well because they listen to cinematographers and through listening, many have become our friends. Cinematography is quite simply in ARRI’s DNA – long may they continue.

Mike Eley BSC – president, British Society Of Cinematographers

On behalf of all BSC members, I’d like to congratulate ARRI on reaching its 100th anniversary. It’s very hard to imagine our industry without those four bold letters, whether it be on a camera, a light or a lens. It remains a reassuring sign of reliability and commitment to getting the shot. To all the people in Munich and across the world working for ARRI - thank you.